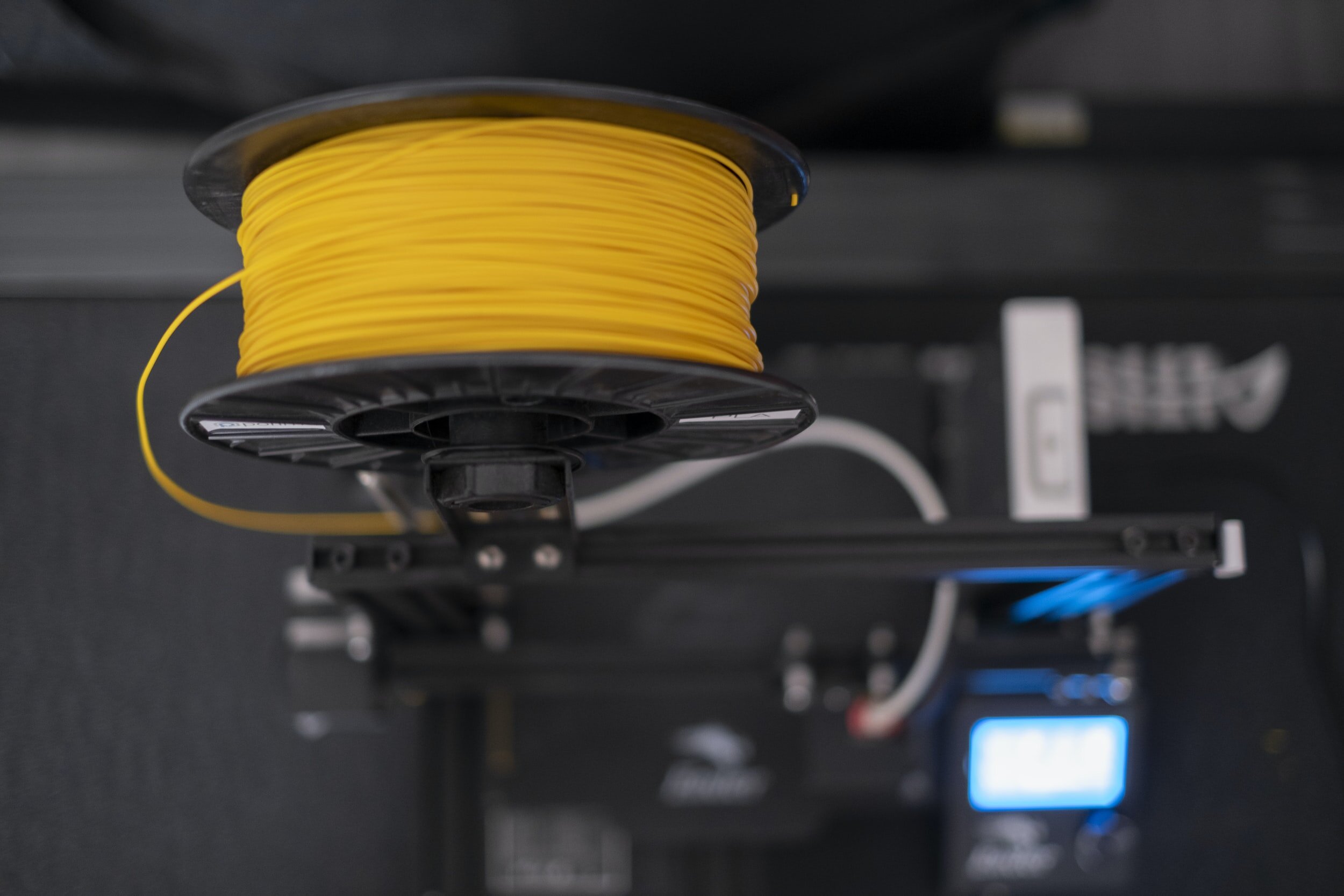

FDM

FDM is the heart of additive manufacturing. FDM prints are ideal for Toys, Décor, Prototypes, and much, much more . With a wide range of materials, there’s an FDM solution for your wildest design ideas.

-

Mechanical Engineering Properties:

Tensile Strength: 60 MPa

Flexural Strength: 70 MPa

Compressive Strength: 60 MPa

Shear Strength: 45 MPa

Young's Modulus: 3.5 GPa

Poisson's Ratio: 0.35

Hardness, Rockwell: 85R

Thermal Engineering Properties:

Melting Temperature: 155-190°C

Glass Transition Temperature: 60-65°C

Coefficient of Thermal Expansion: 70-90 µm/m-K

Thermal Conductivity: 0.13-0.20 W/m-K

Specific Heat Capacity: 1.8 kJ/kg-K

Chemical Engineering Properties:

Water Absorption: 0.3%

Chemical Resistance: PLA is resistant to most common chemicals but is not suitable for prolonged exposure to acids, bases, and organic solvents.

Flammability: PLA is flammable and has a low melting point, making it susceptible to warping and deformation under high heat.

-

Mechanical Properties of ABS:

Tensile Strength: 4,500 to 6,500 psi

Tensile Modulus: 300,000 to 500,000 psi

Elongation at Break: 10% to 50%

Impact Resistance: Excellent toughness and impact resistance

Chemical Properties of ABS:

Solvent Resistance: Resistant to many common solvents

Acid Resistance: Generally resistant to mild acids

Base Resistance: Generally resistant to mild bases

Degradation: May degrade with prolonged exposure to certain chemicals

Thermal Properties of ABS:

Glass Transition Temperature (Tg): 176 to 194°F

Heat Deflection Temperature (HDT): 167 to 194°F

Softening: Becomes pliable above Tg

Thermal Stability: Moderate thermal performance, suitable for many applications

-

Mechanical Properties of Nylon:

Tensile Strength: 6,500 to 11,000 psi

Tensile Modulus: 300,000 to 500,000 psi

Elongation at Break: 80% to 120%

Impact Resistance: Excellent toughness and impact resistance

Chemical Properties of Nylon:

Solvent Resistance: Resistant to many common solvents

Acid Resistance: Generally resistant to mild acids

Base Resistance: Generally resistant to mild bases

Degradation: Minimal degradation with exposure to chemicals

Thermal Properties of Nylon:

Glass Transition Temperature (Tg): 176 to 194°F

Heat Deflection Temperature (HDT): 194 to 230°F

Softening: Becomes pliable above Tg

Thermal Stability: Excellent thermal performance, suitable for high-temperature applications

-

Mechanical Properties of PEBA:

Tensile Strength: 5,000 to 6,500 psi

Tensile Modulus: 180,000 to 300,000 psi

Elongation at Break: 200% to 400%

Impact Resistance: Excellent toughness and impact resistance

Chemical Properties of PEBA:

Solvent Resistance: Resistant to many common solvents

Acid Resistance: Generally resistant to mild acids

Base Resistance: Generally resistant to mild bases

Degradation: Minimal degradation with exposure to chemicals

Thermal Properties of PEBA:

Glass Transition Temperature (Tg): -4 to 32°F

Heat Deflection Temperature (HDT): 122 to 140°F

Softening: Becomes pliable above Tg

Thermal Stability: Good thermal performance, suitable for moderate-temperature applications

-

Mechanical Properties of PC:

Tensile Strength: 9,000 to 14,000 psi

Tensile Modulus: 300,000 to 500,000 psi

Elongation at Break: 5% to 150%

Impact Resistance: Excellent toughness and impact resistance

Chemical Properties of PC:

Solvent Resistance: Resistant to many common solvents

Acid Resistance: Generally resistant to mild acids

Base Resistance: Generally resistant to mild bases

Degradation: Minimal degradation with exposure to chemicals

Thermal Properties of PC:

Glass Transition Temperature (Tg): 302 to 320°F

Heat Deflection Temperature (HDT): 270 to 280°F

Softening: Becomes pliable above Tg

Thermal Stability: Good thermal performance, suitable for moderate-temperature applications

-

Mechanical Properties of Carbon Fiber:

Tensile Strength: 50,000 to 70,000 psi

Tensile Modulus: 4,000,000 to 6,000,000 psi

Elongation at Break: 0.5% to 2%

Impact Resistance: Excellent toughness and impact resistance

Chemical Properties of Carbon Fiber:

Solvent Resistance: Resistant to many common solvents

Acid Resistance: Generally resistant to mild acids

Base Resistance: Generally resistant to mild bases

Degradation: Minimal degradation with exposure to chemicals

Thermal Properties of Carbon Fiber:

Glass Transition Temperature (Tg): Varies depending on the matrix material used

Heat Deflection Temperature (HDT): Varies depending on the matrix material used

Softening: Retains high stiffness and strength at elevated temperatures

Thermal Stability: Excellent thermal performance, suitable for high-temperature applications

-

Coming soon!

Mechanical Engineering Properties:

Tensile Strength: 95 MPa

Flexural Strength: 165 MPa

Compressive Strength: 120 MPa

Shear Strength: 70 MPa

Young's Modulus: 3.6 GPa

Poisson's Ratio: 0.38

Hardness, Rockwell: M100

Thermal Engineering Properties:

Melting Temperature: 343°C

Glass Transition Temperature: 143°C

Coefficient of Thermal Expansion: 52 µm/m-K

Thermal Conductivity: 0.25 W/m-K

Specific Heat Capacity: 1.3 kJ/kg-K

Chemical Engineering Properties:

Water Absorption: 0.5%

Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, including strong acids, bases, and organic solvents.

Flammability: PEEK is highly flame retardant and self-extinguishing.

Biocompatibility: PEEK is biocompatible and is approved for use in medical implants.

SLA

SLA prints achieve resolutions with nearly imperceivable layer heights. SLA prints are great for complex geometries, such as biomedical devices, models, and miniatures. With our state-of-the-art materials, SLA prints can be used in various engineering areas, from fast, accurate prototyping that can survive a wide range of mechanical, chemical, and thermal abuses. Reach out to us if you need help deciding on a material choice for your application!

-

Item description

-

-

Item description

-

-

-

-

Item description

-

Item description

-

Black, White, Amber, Clear