Fabrication at the speed of Innovation

Our Story

SLAM LLC. Isn’t your typical 3D Printing design and fabrication consultant. We started SLAM to make additive manufacturing more available to you! Offering a wide range of materials at a fair price. We also offer our creative problem-solving skills to help you better understand additive manufacturing and how to incorporate it into your workflow.

Our FDM Materials

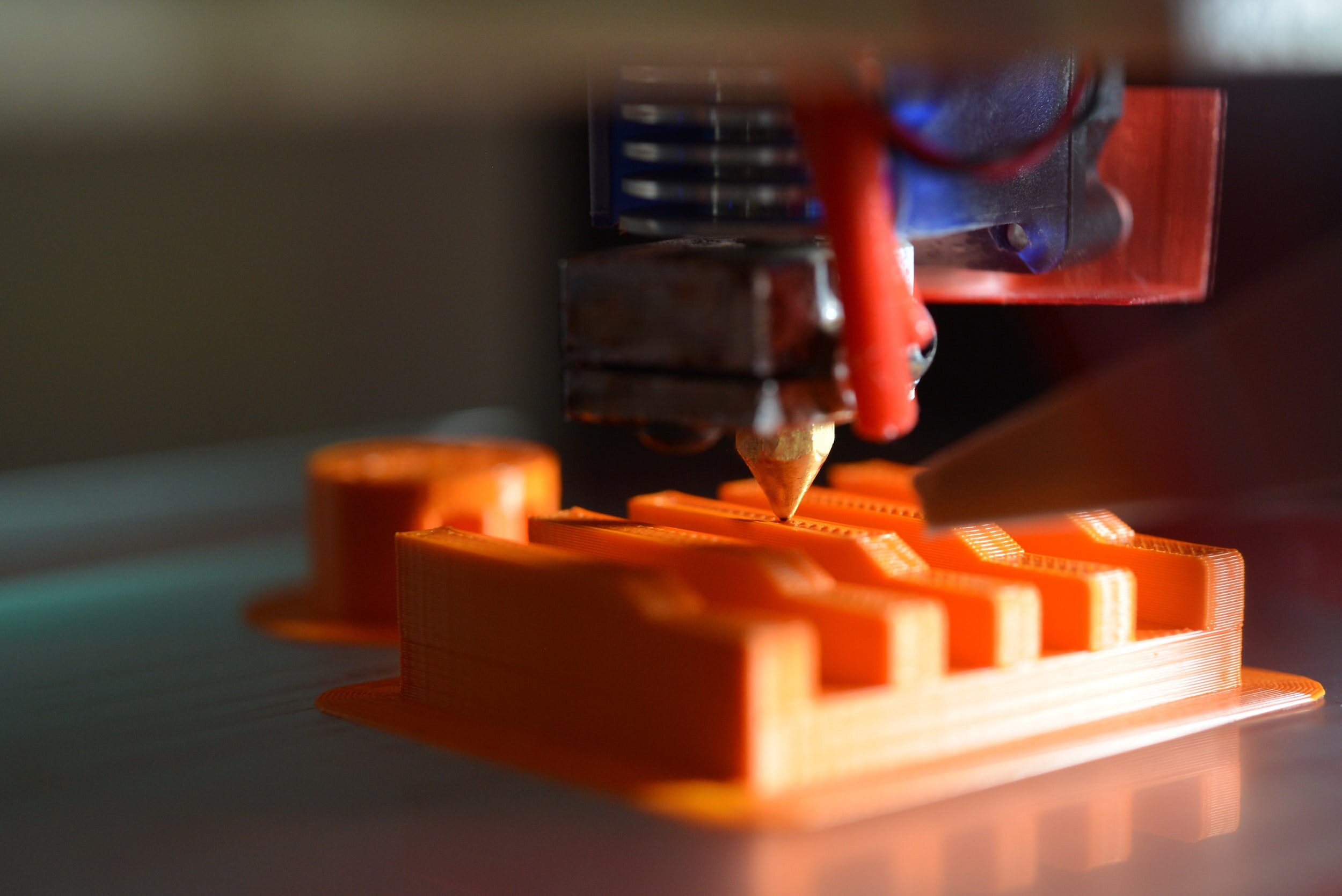

FDM (Fused Deposition Modeling) is a widely used 3D printing process that transforms digital designs into physical objects. It operates by melting thermoplastic filament and precisely depositing it layer by layer onto a heated build plate. The filament is extruded through a heated nozzle, which moves along predetermined trajectories, following the design specifications. As each layer is deposited and solidifies, the hotend raises, creating complex and intricate geometries.

FDM 3D printing offers versatility in material selection, allowing for a wide range of options to suit specific application requirements. It is a cost-effective and accessible process that has gained popularity in various industries for rapid prototyping, low-volume production, and DIY projects.

-

PLA (Polylactic Acid) is a biodegradable and compostable thermoplastic material commonly used in 3D printing. It is made from renewable resources such as corn starch or sugarcane, making it an environmentally friendly option.

PLA is known for its ease of use and low printing temperature, making it a great choice for beginners. It has a low warping and shrinkage rate, resulting in high accuracy and precision in printed parts.

PLA has a glossy and smooth finish, making it ideal for printing objects with intricate details and designs. It comes in various colors, allowing creative freedom in 3D printing projects.

However, it is important to note that PLA is not as strong or heat-resistant as other 3D printing materials such as ABS or Nylon. It has a lower melting point and can become brittle over time.

PLA is a great option for eco-conscious 3D printing enthusiasts and those looking for user-friendly material for creating detailed and intricate prints.

-

ABS is popular among customers seeking durability, strength, and flexibility in their printed creations. ABS (Acrylonitrile Butadiene Styrene) is a well-established thermoplastic known for its excellent mechanical properties, making it ideal for a wide range of applications.

One of the key advantages of ABS filament is its exceptional durability. It offers high-impact resistance, ensuring that your printed parts can withstand demanding conditions and everyday use. Whether you're prototyping, manufacturing functional parts, or creating artistic designs, ABS filament ensures that your creations will be robust and long-lasting.

Furthermore, ABS filament provides superior strength, allowing you to print parts with structural integrity. This makes it suitable for applications that require load-bearing components or parts that need to withstand mechanical stress. With ABS filament, you can confidently create functional prototypes, tooling, and end-use products that meet your specific requirements.

In addition to its durability and strength, ABS filament offers various finishes and post-processing options, allowing you to refine your printed parts' appearance and surface quality.

Whether you're a professional designer, engineer, hobbyist, or educator, ABS filament is a reliable and versatile choice to bring your ideas to life.

-

Nylon filament is an exceptional material choice that delivers outstanding results across various applications. Known for its durability, strength, and flexibility, Nylon filament allows us to create functional and visually stunning parts that meet your exact specifications.

Regarding durability, Nylon filament is in a league of its own. It offers excellent mechanical properties, including high impact resistance and toughness. This means the parts we create using Nylon filament can withstand demanding environments and maintain their integrity over time, making it an ideal choice for functional prototypes and end-use parts.

Additionally, Nylon filament offers remarkable strength while retaining flexibility. This unique combination enables us to produce intricate designs that require some degree of flexibility, such as snap-fit connections, living hinges, and complex geometries. The versatility of Nylon filament allows us to turn your ideas into reality, ensuring that your printed parts have both strength and functionality.

Another key advantage of Nylon filament is its excellent chemical resistance. This property makes it suitable for applications that require exposure to various chemicals or harsh environments. Whether you need parts for chemical processing, industrial equipment, or specialized components, Nylon filament ensures that your designs can withstand the challenges they may encounter.

-

PEBA (Polyether Block Amide) filament is known for its impressive combination of flexibility, durability, and resilience. It offers excellent elasticity, allowing production parts to be bent, stretched, and compressed without losing shape or functionality. PEBA filament is ideal whether you require flexible prototypes, soft-touch components, or parts with dynamic properties.

Durability is another notable feature of PEBA filament. It exhibits remarkable resistance to impact and abrasion, ensuring that your printed parts can withstand the challenges of real-world applications. This makes it suitable for functional prototypes, industrial components, and parts requiring flexibility and toughness.

PEBA filament also offers excellent chemical resistance, making it suitable for applications involving exposure to oils, solvents, and various chemicals. It can maintain its integrity and functionality even in demanding environments, giving you peace of mind that your printed parts will perform reliably.

In addition to its physical properties, PEBA filament provides superb layer adhesion and printability. With our advanced 3D printing techniques and state-of-the-art equipment, we can achieve precise and detailed prints using PEBA filament.

-

Carbon Fiber filament combines the strength of carbon fiber with the versatility of traditional filament materials. It is composed of a base polymer infused with carbon fiber particles, resulting in a filament that exhibits exceptional stiffness and tensile strength. This makes it an ideal choice for applications that demand lightweight parts without sacrificing structural integrity.

One of the standout features of Carbon Fiber filament is its impressive strength-to-weight ratio. It is significantly stronger than standard filament materials, such as ABS or PLA, and considerably lighter. This property allows for the production of strong and lightweight parts, making it perfect for aerospace, automotive, and robotics applications, among others.

Additionally, Carbon Fiber filament offers excellent dimensional stability. It has minimal warping and shrinkage during printing, ensuring that your designs maintain their precise shape and dimensions. This makes Carbon Fiber filament a reliable choice for producing intricate and complex parts with high accuracy.

Moreover, Carbon Fiber filament provides excellent resistance to impact and wear. It can withstand heavy loads and resist deformation, making it suitable for creating functional prototypes, jigs, fixtures, and other parts that require durability and long-term performance.

-

PC (Polycarbonate) filament is renowned for its outstanding strength, durability, and heat resistance. It is an ideal choice for applications that require robust and resilient parts that can withstand demanding conditions. Whether you're creating functional prototypes, engineering components, or end-use products, PC filament ensures that your prints can handle the challenges of real-world use.

One of the standout features of PC filament is its exceptional mechanical properties. It offers high impact resistance, making it suitable for parts that must withstand heavy loads or potential impacts. Additionally, PC filament exhibits excellent stiffness, enabling the production of parts with structural integrity and dimensional stability.

PC filament also excels in heat resistance, allowing it to maintain its properties even at elevated temperatures. This property makes it ideal for automotive, aerospace, and electronics applications, where parts may be exposed to high heat or thermal stress.

Moreover, PC filament provides excellent optical clarity, making it suitable for applications that require transparent or translucent parts. From lenses and covers to light guides and fixtures, PC filament enables us to create visually appealing and functional components that meet your specific requirements.

-

Item description

-

PEEK filament is renowned for its outstanding mechanical properties, making it the ultimate choice for applications that require robust, durable, and chemically inert parts. It offers exceptional strength, with a tensile strength comparable to some metals. This enables the production of functional prototypes, end-use components, and parts that require structural integrity in demanding environments.

One of the standout features of PEEK filament is its exceptional heat resistance. It can withstand high temperatures without melting or deforming, making it suitable for applications involving extreme heat or thermal stress exposure. This property makes PEEK filament a preferred choice in aerospace, automotive, and industrial applications, where parts must maintain their performance under harsh conditions.

Moreover, PEEK filament exhibits excellent chemical resistance, making it resistant to many solvents, acids, and other harsh chemicals. This enables the creation of parts that can withstand exposure to aggressive environments, making PEEK filament suitable for applications in chemical processing, medical devices, and more.

Additionally, PEEK filament offers superb dimensional stability, ensuring that your printed parts maintain their shape and dimensions over time. This property is crucial for creating precise and accurate parts, especially for applications that require tight tolerances or intricate geometries.

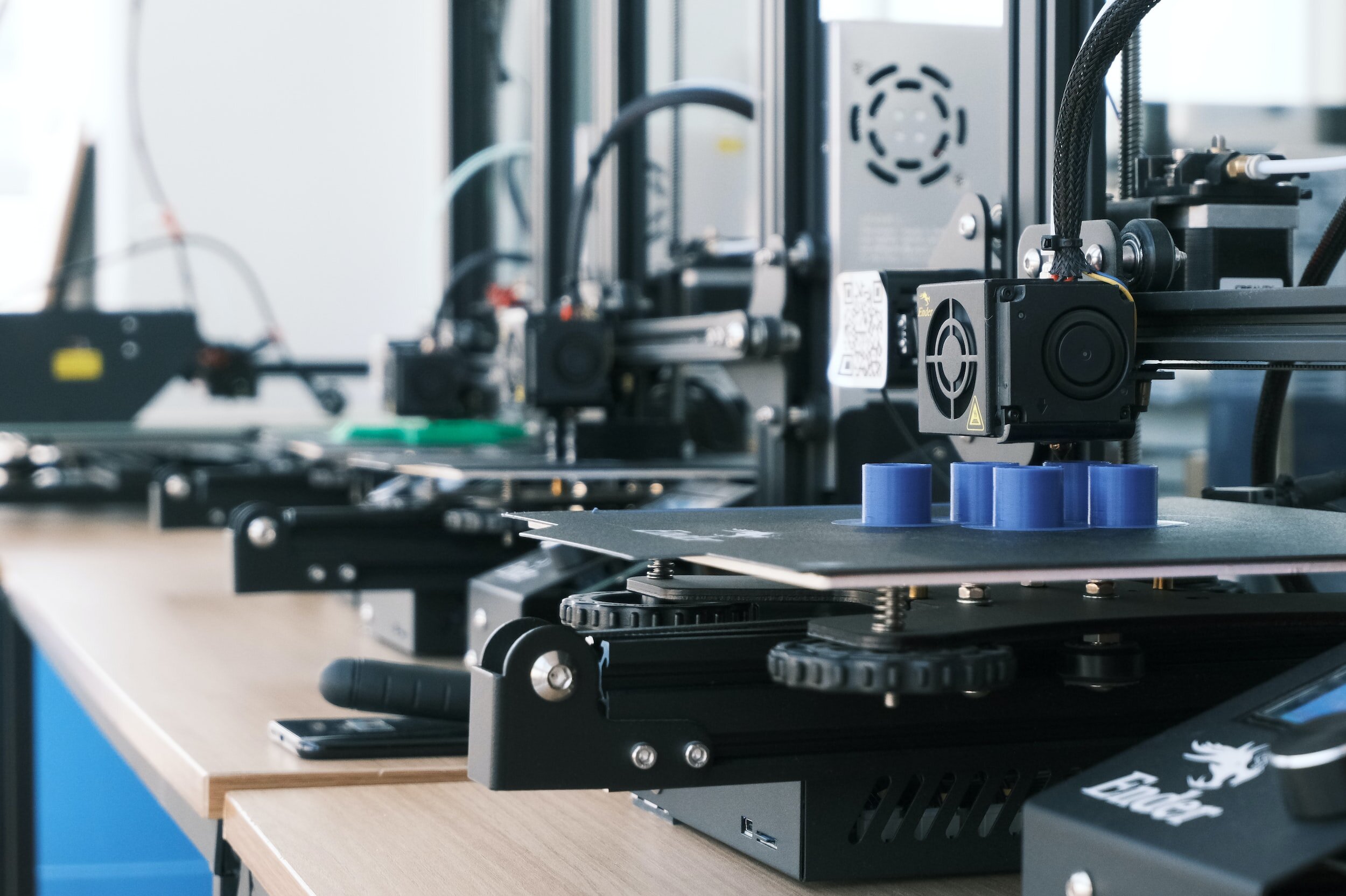

FDM SOLUTIONS

Open the form to the right to receive email-to-quote services.

At SLAM, FDM technology takes center stage, offering you the highest quality prints with unmatched accuracy and reliability. With our advanced FDM printers, we can bring your concepts to life with remarkable precision and attention to detail. Whether you're an engineer, product designer, or simply an enthusiast looking to materialize your creative visions, our FDM capabilities are tailored to meet your unique requirements.

FDM printing is a highly versatile and widely used technique that leverages the power of thermoplastics to build three-dimensional objects layer by layer. One of the significant advantages of FDM printing is its extensive material selection, offering a wide range of options to choose from. Whether you need parts with high strength, flexibility, transparency, or heat resistance, our FDM printers can handle various materials, including ABS, PLA, PET-G, and more.

Regarding prototyping, FDM printing shines as a cost-effective and time-efficient solution. With our FDM technology, you can quickly iterate and test multiple design iterations without the need for expensive tooling or lengthy production processes. FDM's ability to produce functional prototypes with complex geometries and intricate details allows you to evaluate your designs thoroughly and make necessary adjustments before moving forward to production, saving time and resources.

Furthermore, FDM printing offers excellent geometric accuracy, ensuring that your prototypes closely resemble the final product. This is particularly advantageous for engineering design, as it allows for comprehensive testing and analysis of functional aspects, such as form, fit, and assembly. Our FDM printers can achieve fine-layer resolutions, resulting in smooth surfaces and crisp details, enhancing the overall quality of your prints.

While FDM printing boasts numerous advantages, it's important to consider some limitations. One such consideration is the visible layer lines that may be present on the surface of the printed objects. However, our advanced post-processing and high-precision printing techniques minimize can help to minimize these lines, providing you with a refined and professional finish.

Our SLA Materials

SLA (Stereolithography laser annealing) is a widely used 3D printing process that transforms digital designs into physical objects. It operates by curing resin precisely layer by layer onto a build plate with lasers. The laser moves along predetermined trajectories, following the design specifications. As each layer is cured, the build platform raises, allowing for the creation of complex and intricate geometries.

SLA 3D printing offers versatility in material selection, allowing for a wide range of options to suit specific application requirements. It is a cost-effective and accessible process that has gained popularity in various industries for rapid prototyping, low-volume production, and DIY projects.

-

One of the key advantages of SLA Engineering Material lies in its remarkable precision. With a high degree of dimensional accuracy and fine details, these materials enable you to easily produce intricate designs and parts. Exceptional printing resolution ensures that every feature, no matter how small or complex, is captured flawlessly, giving you the confidence to bring your most ambitious ideas to life.

Moreover, SLA Engineering Materials are engineered to deliver superior durability. They boast excellent mechanical properties, including high strength, toughness, and resistance to wear, making them ideal for applications that demand structural integrity and long-term reliability. Whether you're creating functional prototypes, jigs, fixtures, or end-use parts, these materials guarantee exceptional performance, withstanding the rigors of real-world use.

In addition to its precision and durability, SLA Engineering Materials offer exceptional versatility. A wide range of engineering-grade resins allows you to choose the specific properties that best suit your project requirements. Whether you need heat resistance, chemical resistance, or biocompatibility, SLA Engineering Material provides a flexible platform to meet your diverse needs.

From the aerospace and automotive industries to healthcare and consumer electronics, these revolutionary materials empower you to push the boundaries of innovation, delivering high-quality, functional parts that meet the most demanding specifications. Elevate your 3D printing capabilities with Resin Engineering Materials and experience the future of precision and durability in engineering manufacturing.

-

ABS-Like Resin is the perfect choice for customers seeking durability, strength, and versatility in their printed parts. This advanced resin combines the renowned qualities of ABS (Acrylonitrile Butadiene Styrene) with the precision and flexibility of 3D printing technology, providing you with an unmatched solution for your projects.

When it comes to durability, ABS-Like Resin truly shines. Its high impact resistance ensures that your printed parts can withstand the harshest conditions, making it ideal for functional prototypes, industrial components, and parts that require exceptional strength and longevity. You can trust that your creations will withstand rigorous handling and perform reliably throughout their lifespan.

But that's not all - ABS-Like Resin offers exceptional versatility. It allows you to achieve various properties and finishes, tailoring the material to your specific application needs. Whether you need rigidity, flexibility, or heat resistance, this resin delivers the desired characteristics, ensuring that your parts meet the unique requirements of your projects.

Moreover, ABS-Like Resin is compatible with various post-processing techniques, such as sanding, painting, and chemical finishing. This means you can customize your printed parts' appearance and surface quality, resulting in visually stunning and professional-grade components for various industries.

Experience the power of ABS-Like Resin and unlock a world of possibilities in creating functional, high-quality parts that meet your specifications.

-

High-precision resins are perfect when looking for a model with accurate form. High-precision resins are more brittle than other SLA resins and are not recommended for functional models.

-

Discover the limitless potential of bio-compatible 3D printing with our exceptional range of bio-compatible 3D printing resins. Specially curated to cater to the needs of biomedical professionals, our carefully selected resins offer a unique blend of biocompatible materials that ensure optimal safety and reliability in your 3D-printed creations. Unleash your creativity and explore various applications, from prototyping medical devices to fabricating anatomical models and prosthetics. Our bio-compatible resins seamlessly integrate with existing 3D printers, allowing you to transform your designs into tangible, biocompatible objects effortlessly. With our high-quality resins at your disposal, you can confidently embark on innovative projects in tissue engineering, personalized medicine, and regenerative therapies. Harness the power of bio-compatibility and unlock a new world of possibilities in 3D printing with our exceptional bio-compatible resins.

SLA SOLUTIONS

Open the form to the right to receive email-to-quote services.

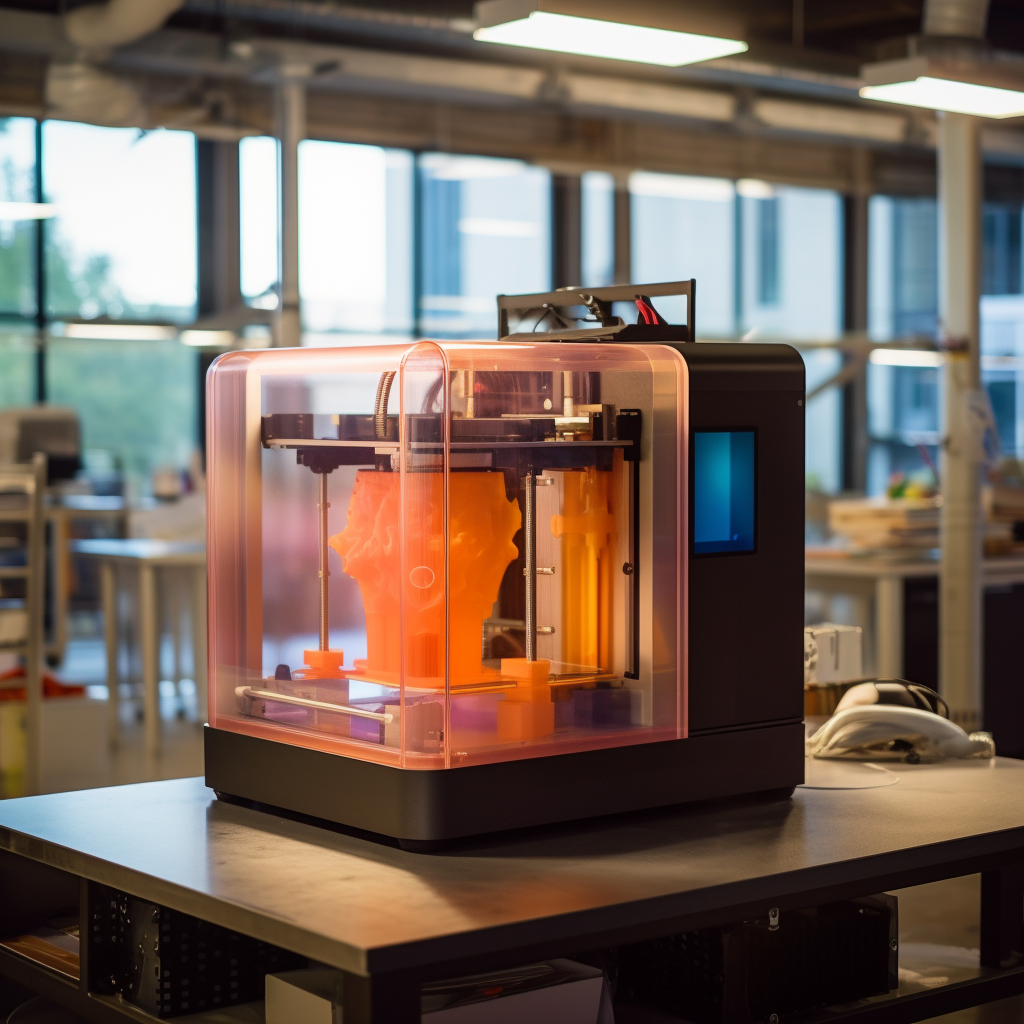

SLA technology is a testament to our commitment to excellence, allowing us to bring your ideas to life with utmost accuracy and attention to detail. With our state-of-the-art SLA printers, we can transform your concepts into tangible reality, capturing the intricacies of your designs with unparalleled finesse. Whether you're an engineer, industrial designer, or visionary seeking to materialize your wildest dreams, our SLA capabilities are tailored to meet your unique requirements.

SLA printing utilizes a precise laser to cure liquid photopolymer resin layer by layer, resulting in astonishingly detailed and smooth prints. One major advantage of SLA printing is its ability to produce intricate and complex geometries with exceptional surface quality. Our SLA printers can achieve fine resolutions, ensuring that every minute detail of your design is faithfully reproduced, creating stunning prototypes and models that closely resemble the final product.

Regarding prototyping, SLA printing offers numerous benefits that are hard to overlook. The high precision and resolution of SLA prints enable you to thoroughly evaluate and validate your designs, allowing for accurate form, fit, and functional testing. This empowers engineers and designers to identify and address any potential issues early in the development process, saving valuable time and resources.

Furthermore, SLA printing boasts a wide selection of advanced photopolymer materials with distinct properties and characteristics. From high-temperature resistance to exceptional mechanical strength, these materials cater to various application requirements, ensuring that your prototypes possess the desired attributes for testing and validation.

However, it's important to consider a few limitations of SLA printing. The resin-based nature of the process may result in more brittle objects than other 3D printing methods. While SLA prints can be structurally sound, certain designs with thin, delicate features may be prone to breakage. It's essential to carefully evaluate your design and consult with our knowledgeable team to ensure optimal printability and durability.

SLA printing typically involves a post-processing step to remove excess resin and cure the prints fully. This may add some additional time to the production process. However, rest assured that our meticulous post-processing techniques deliver prints with refined finishes, ensuring that your prototypes are ready for evaluation and presentation.

DESIGN & PROTOTYPING SOLUTIONS AND SERVICES

Open the form to the right to receive email-to-quote services.

SLAM is where expertise, creativity, and precision converge. With over a decade of design experience, we have established ourselves as a leader in the industry, providing innovative solutions tailored to your specific needs. Our deep understanding of design principles and familiarity with ASME Y14.5 standards ensure that every project we undertake adheres to the highest level of quality and professionalism.

Our team of highly skilled designers and engineers brings a wealth of knowledge and expertise to the table, enabling us to tackle projects across a wide range of industries. From mechanical, biomedical, and automated systems, we possess the technical acumen and creativity to bring your innovative concepts to life with the utmost precision and efficiency.

With our cutting-edge 3D printing capabilities, we excel in transforming your ideas into tangible prototypes that showcase the highest level of craftsmanship. Our prototyping expertise extends to the mechanical and automated fields, allowing us to bring complex mechanisms, intricate components, and automated systems to life in a rapid and cost-effective manner.

We understand the critical importance of adhering to ASME Y14.5 standards in engineering design. Our familiarity with these industry guidelines ensures that your projects meet the highest level of accuracy, tolerances, and geometric dimensioning and tolerancing (GD&T). We pay meticulous attention to detail, ensuring that every design element is precisely defined and that the manufactured components fully comply with the required standards.

Furthermore, our 3D printing and prototyping capabilities enable us to rapidly iterate and refine designs, significantly reducing development cycles and time to market. By leveraging our advanced technology, you can evaluate and test your designs before committing to costly production runs, saving you both time and resources.

Our commitment to excellence extends beyond the technical aspects of design and prototyping. We strive to foster collaborative partnerships with our clients, actively listening to your unique requirements, goals, and challenges. Our team works closely with you throughout the design and prototyping process, providing expert guidance and ensuring that the final product meets and exceeds your expectations.